Textile manufacturing is the backbone of the global fashion industry, covering the transformation of fibers into fabrics and fabrics into finished products such as clothing, upholstery, and industrial materials. This dynamic sector had a global market size valued at $1.16 billion in 2025 and is projected to grow at a CAGR of 4.2% from 2026 to 2033, fueled by rising demand for sustainable and technologically advanced textiles.

Why does it matter? Beyond clothing, textiles play a crucial role in sectors like healthcare, agriculture, and construction. However, challenges like environmental impact and resource scarcity are reshaping how the industry operates. From cotton spinning in traditional mills to modern systems powered by AI, textile manufacturing remains at the forefront of industrial innovation.

With advanced trend forecasting solutions like Heuritech, brands can anticipate shifts in material demand, optimize production planning, and reduce waste—ensuring a more sustainable and data-driven approach to textile manufacturing.

The basics of textile manufacturing

Textile manufacturing is the process of transforming raw fibers into finished materials like fabrics and clothing. It begins with fiber sourcing, which can be natural (cotton, wool, silk) or synthetic (polyester, nylon). While cotton remains the most widely used natural fiber, synthetic fibers dominate modern production due to their durability and cost efficiency. However, their widespread use comes with significant environmental concerns: synthetic textiles are derived from petrochemicals and contribute to microplastic pollution, with textiles accounting for approximately 9% of annual microplastic losses to the ocean. The production and washing of synthetic fabrics release plastic particles that persist in ecosystems, highlighting one of the fashion industry’s most pressing sustainability challenges.

The process includes:

Spinning: Converting fibers into yarn by twisting them for strength.

Weaving or knitting: Turning yarn into fabric through interlacing or looping techniques.

Dyeing and finishing: Adding color and texture to fabrics, as well as treatments like water resistance or anti-wrinkle properties.

Traditionally, much of this work was done manually or on basic looms, but today, automation and advanced machinery are the norm. This shift ensures greater efficiency, quality control, and the ability to produce fabrics at scale.

Whether it’s a soft wool sweater or a synthetic outdoor jacket, the fundamentals of textile manufacturing remain rooted in turning fibers into materials that serve functional and aesthetic purposes.

Challenges facing the textile industry

Textile manufacturing is evolving under immense pressure to address sustainability, supply chain fragility, and workforce transitions. These challenges are interconnected, demanding a holistic response from the industry.

Sustainability pressures

Sustainability in the textile industry is no longer optional—it’s a necessity. Textile production is among the most resource-intensive industries, with severe environmental impacts at every stage of the supply chain.

One of the most pressing concerns is water consumption. Producing a single cotton shirt requires approximately 2,700 liters of water, enough to meet an individual’s drinking needs for over two years. The textile sector was the third-largest contributor to water degradation and land use in the EU in 2020, consuming an average of nine cubic meters of water per person annually. Additionally, textile dyeing is responsible for 20% of global industrial water pollution, with dye effluents contaminating rivers and oceans, increasing chemical oxygen demand, and threatening aquatic biodiversity.

Beyond water pollution, textile waste and microplastics represent a growing environmental crisis. Every year, the industry generates vast amounts of waste—on average, Europeans discard 11 kg of textiles per person annually, with 87% ending up in landfills or incinerators. Only 1% of used clothing is recycled into new garments, as existing recycling technologies struggle to break down complex fiber blends. Furthermore, synthetic textiles like polyester release microplastics into waterways. A single laundry load of polyester garments can shed 700,000 microplastic fibers, which accumulate in marine ecosystems and the food chain. More than half a million tonnes of microplastics from textiles settle in the ocean floor annually.

Faced with these challenges, manufacturers are pivoting toward more sustainable solutions, such as:

- Recycled fibers, reducing reliance on virgin raw materials and limiting waste. Some brands are incorporating post-consumer textile waste or using ocean plastic to create new fabrics.

- Waterless dyeing technologies, such as CO₂-based dyeing systems, which eliminate the need for water and significantly reduce chemical runoff.

- Circular production models, where waste fabrics are reintegrated into new products, reducing landfill waste and extending product lifecycles.

- Eco-friendly dyeing alternatives, including biodegradable and plant-based dyes, which minimize the harmful effects of synthetic dyes on human health and aquatic life.

Governments and regulatory bodies are also stepping in to address the industry’s footprint. The EU Strategy for Sustainable and Circular Textiles, introduced in 2022, mandates ecodesign requirements, digital product passports, and extended producer responsibility (EPR) schemes, holding brands accountable for the entire lifecycle of their products. By 2025, EU countries will be required to collect textiles separately for reuse and recycling.

While progress is being made, the road to sustainability requires continued innovation and systemic change. Shifting towards circularity, embracing slow fashion principles, and adopting cutting-edge technologies will be critical to mitigating fashion’s environmental toll while aligning with growing consumer demand for responsible production.

Supply chain complexities

Global supply chains in the textile industry have become increasingly fragile, with multiple risk factors disrupting operations at various stages—from raw material sourcing to production and logistics.

Raw material shortages & climate change

Extreme weather events and climate change are significantly impacting the availability of raw materials. Droughts, floods, and rising temperatures are affecting cotton-growing regions, leading to lower yields and reduced quality. In recent years, droughts in major cotton-producing countries such as India, the U.S., and China have constrained supply, forcing manufacturers to seek alternative fiber sources. Additionally, heatwaves and erratic rainfall patterns are making it harder for farmers to plan their production cycles, increasing unpredictability in the market.

Commodity volatility & market uncertainty

The textile industry now faces a new challenge: persistent market unpredictability. Since peaking at 164 cents per pound in May 2022, cotton prices have steadily declined, ending 2024 at 79.91 cents.

In 2025, the market experienced a “fragile stabilization” with a downward trend. By September 2025, the Cotton Outlook A Index dropped to $0.7798, and as of December 18, 2025, futures prices hit 63.52 cents, reflecting a 6.38% annual decline. This volatility is fueled by sluggish global demand, with production down 2% in 2025, and rising production costs (energy and labor) that continue to squeeze margins despite falling fiber prices.

Moreover, structural fragilities like climate-driven supply shocks in India and currency fluctuations keep the market on edge. For brands, the challenge has shifted from managing high costs to mitigating inventory risk: buying too early in a deflationary market can lead to overvalued stocks. In this “low-price but high-risk” era, data-driven forecasting is essential to navigate erratic shifts and ensure long-term profitability.

The push for diversification & resilient supply chains

To counteract these challenges, companies are adopting diversified supply chain strategies aimed at increasing flexibility and reducing risk exposure. Some key approaches include:

- Nearshoring & regionalized production: Brands are relocating manufacturing closer to consumer markets to shorten lead times and reduce transportation dependencies. This trend is particularly noticeable in Europe (with increased production in Turkey and Portugal) and North America (with Mexico and Central America emerging as key production hubs).

- Supplier diversification: Rather than relying on a single supplier or region, businesses are expanding their sourcing networks across multiple countries to ensure continuity even in the face of localized disruptions.

- Digitization & supply chain transparency: Companies are investing in AI-driven demand forecasting, blockchain-based traceability, and real-time tracking systems to enhance supply chain visibility and predict potential disruptions before they escalate.

As the textile industry continues to navigate these complex challenges, building resilient, adaptive, and sustainable supply chains will be crucial for long-term success.

Workforce and automation

Automation has reshaped textile production by streamlining tasks like spinning and weaving, improving efficiency and reducing costs. However, this shift threatens millions of jobs in labor-dependent regions such as Southeast Asia. To bridge the gap, manufacturers are investing in upskilling programs, training workers in digital tools and machine operation to transition into higher-value roles. At the same time, hybrid workflows are emerging, where automation handles repetitive tasks while human expertise ensures quality control and craftsmanship. Balancing automation with workforce adaptability is key to a sustainable transition

Balancing quality and scale

As consumers demand higher-quality, customized products, manufacturers face new challenges:

- Ensuring uniform fabric quality across large batches.

- Meeting niche customization needs without disrupting mass production.

AI-powered tools are emerging as a solution, offering predictive maintenance for machinery and enabling agile production systems that can adapt to varying demands.

Key trends in textile manufacturing for 2025

The textile manufacturing landscape is evolving rapidly, driven by changing consumer demands, technological advancements, and global market dynamics. Here are the key trends shaping the industry in 2025, based on our predictive insights at Heuritech.

1. Sustainable textiles take center stage

Sustainability is not just a buzzword—it’s a necessity. Consumers and regulators alike demand greener practices, prompting manufacturers to adopt:

- Recycled materials: Polyester made from post-consumer plastics and textiles.

- Organic fibers: Cotton and wool grown with minimal chemical inputs.

- Waterless processes: Technologies reducing dyeing water use by up to 90%, such as ECOHUES™, which replaces water with a recyclable non-aqueous solvent, cutting water usage by 95%, and DyeCoo, which uses pressurized CO₂ instead of water, eliminating wastewater discharge entirely.

By 2030, the global sustainable fashion market is projected to grow from USD 15.01 billion in 2025 to USD 47.48 billion, reflecting a CAGR of 15.48%. As we move into 2026, this growth is being accelerated by the phased implementation of the EU’s Digital Product Passport (DPP) and the Ecodesign for Sustainable Products Regulation (ESPR). These frameworks are pushing manufacturers to move beyond marketing claims toward verifiable transparency.

In 2026, the focus is shifting toward “textile-to-textile” recycling to meet these new European standards, which prioritize durability and fiber purity. This regulatory pressure is turning sustainability into a core operational requirement, forcing the industry to invest in chemical recycling technologies that can handle complex fiber blends—the final hurdle in achieving a truly circular production model.

2. Localization of production

The shift towards localized production in the fashion industry is more nuanced than a straightforward move away from global supply chains. While nearshoring and regionalization are gaining traction—allowing brands to reduce shipping costs and supply chain bottlenecks—this is not a universal trend. Many companies still rely on global sourcing, with China alone accounting for 36.5% of all imported clothing items in the U.S..

Geopolitical factors are also shaping sourcing strategies. Brands are increasingly selecting suppliers from geopolitically aligned regions, leading to a shortened sourcing footprint in countries like China, Germany, the UK, and the US. However, full localization remains challenging due to the need for specialized skills, higher local production costs, and raw material availability.

As a result, many fashion brands adopt hybrid supply chain strategies, blending global and local sourcing to balance cost, speed, and resilience. This approach allows them to adapt to disruptions while maintaining flexibility in production and distribution.

3. Demand for performance fabrics

Functionality is no longer optional in textiles. The growing athleisure and outdoor wear markets are driving demand for:

- Moisture-wicking and odor-resistant fabrics.

- Stretchable, breathable fabrics ideal for active lifestyles.

- Weatherproof textiles, including UV-blocking and waterproof materials.

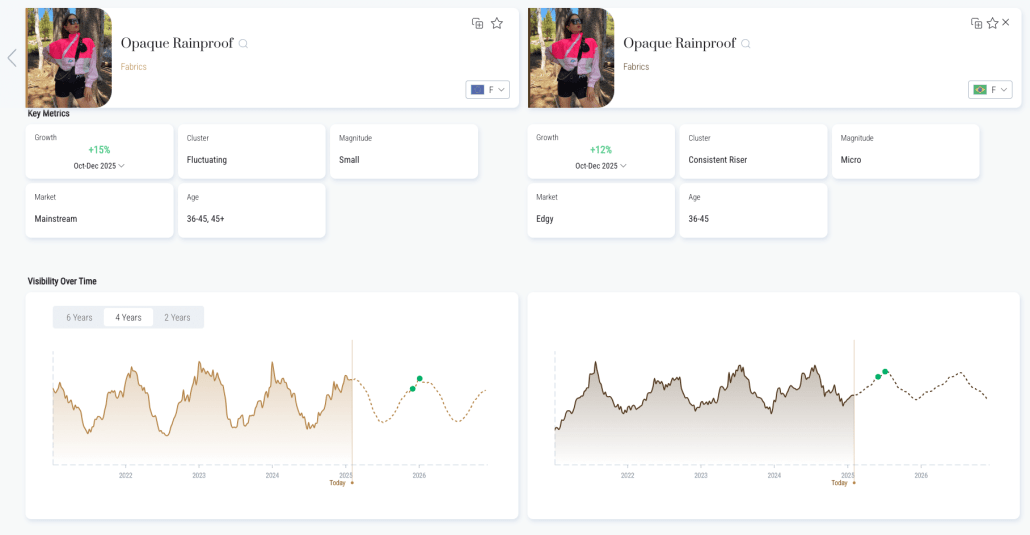

According to Heuritech data, opaque rainproof fabric will grow 15% during the Winter 2025 season in Europe, and 12% in Brazil:

Image: Data from Heuritech Trend Forecasting Platform

By 2026, the performance fabrics market is estimated to reach approximately USD 88.9 billion, on its way to a projected USD 108.02 billion by 2030. This steady growth, maintaining a CAGR of roughly 5.1%, is no longer just fueled by sportswear. In 2026, we see a massive expansion into “Smart Textiles” fabrics with embedded sensors for health monitoring and “Bio-Synthetics” derived from algae or food waste, which offer the same durability as polyester without the microplastic footprint. This makes performance fabrics a critical sector for brands looking to combine technical excellence with the circular economy.

4. Customization and on-demand manufacturing

Modern consumers seek individuality, and brands are responding with on-demand production:

- Digital printing enables high-quality, customizable designs at scale.

- On-demand systems eliminate overproduction, reducing inventory by up to 40%.

- Small-batch, personalized collections are becoming mainstream, especially in premium and luxury markets.

5. The rise of circular fashion

The shift towards circularity is redefining how textiles are produced and consumed:

- Fabric recycling technologies can convert used garments into new fibers.

- Take-back programs incentivize consumers to return old clothing for reprocessing.

- Brands incorporating circular practices are expected to see higher consumer loyalty, with surveys showing 60% of shoppers prioritize sustainable options.

6. Emerging markets in textile manufacturing

New regions are gaining prominence in textile production:

- Africa: Nations like Ethiopia and Kenya are becoming low-cost manufacturing hubs with an emphasis on ethical production.

- South America: Countries such as Brazil are focusing on bio-based textiles derived from local resources.

Emerging markets are diversifying global production networks and introducing innovative, locally sourced materials.

7. Digitization of the textile industry

The textile industry is undergoing a major digital transformation, but the shift is more measured than hype suggests. By 2026, the AI-in-fashion market is estimated to reach approximately USD 3 to 4 billion, growing at a robust CAGR of nearly 40% as we head toward the mid-2030s.

This growth is driven by tangible efficiency gains: Generative AI is now optimizing pattern cutting, with pilot programs demonstrating a 10-15% reduction in textile waste. Simultaneously, Digital Twins are being used to simulate virtual production lines, allowing manufacturers to identify bottlenecks before physical assembly begins. While these technologies are accelerating the industry’s evolution, “Zero Waste production” remains an aspirational goal for most; however, the transition from pilot projects to industrial-scale implementation in 2026 marks a turning point for data-driven manufacturing.

Heuritech’s Insights: Empowering the Global Textile Business

At Heuritech, our AI-powered solutions offer precise, data-driven forecasts for the main stages of production. In an era where trade volatility affects major production hubs like India, our technology ensures that your production is perfectly aligned with real-world demand.

By predicting fabric preferences and apparel trends, we help your business optimize the entire manufacturing process. Our insights empower your brand to move beyond the manual loom and innovate with confidence.

If you want to see our technology in action, we invite you to request a demo. Experience firsthand how our AI-driven insights can help your brand stay ahead of trends, optimize production, and make informed decisions in a shifting global market.